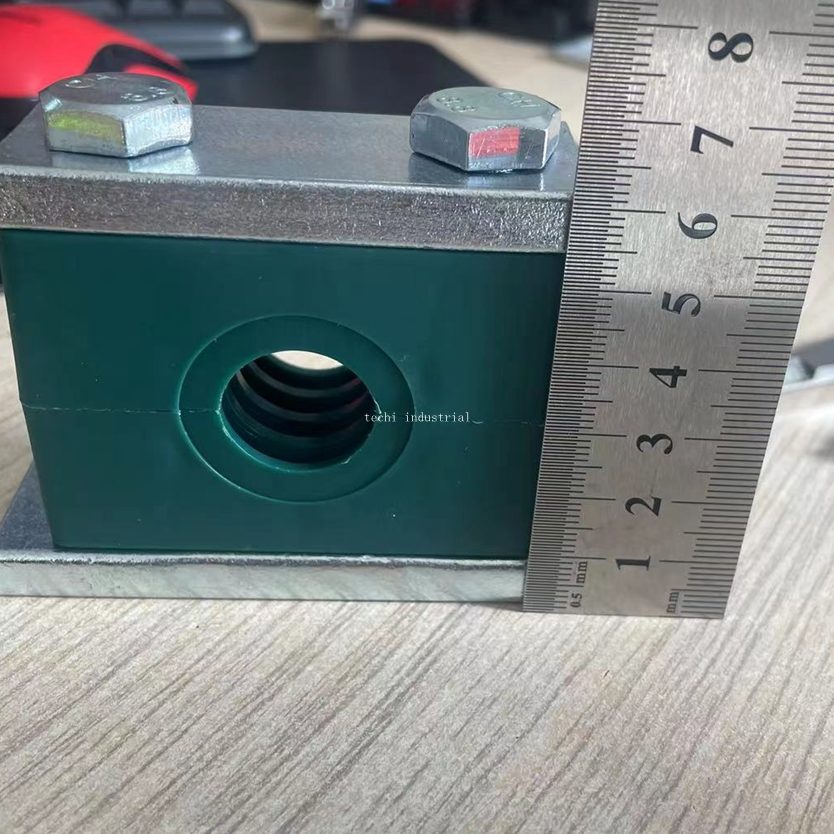

Standard Series Polyamide PA Tube Clamp Body 6mm 6.3mm

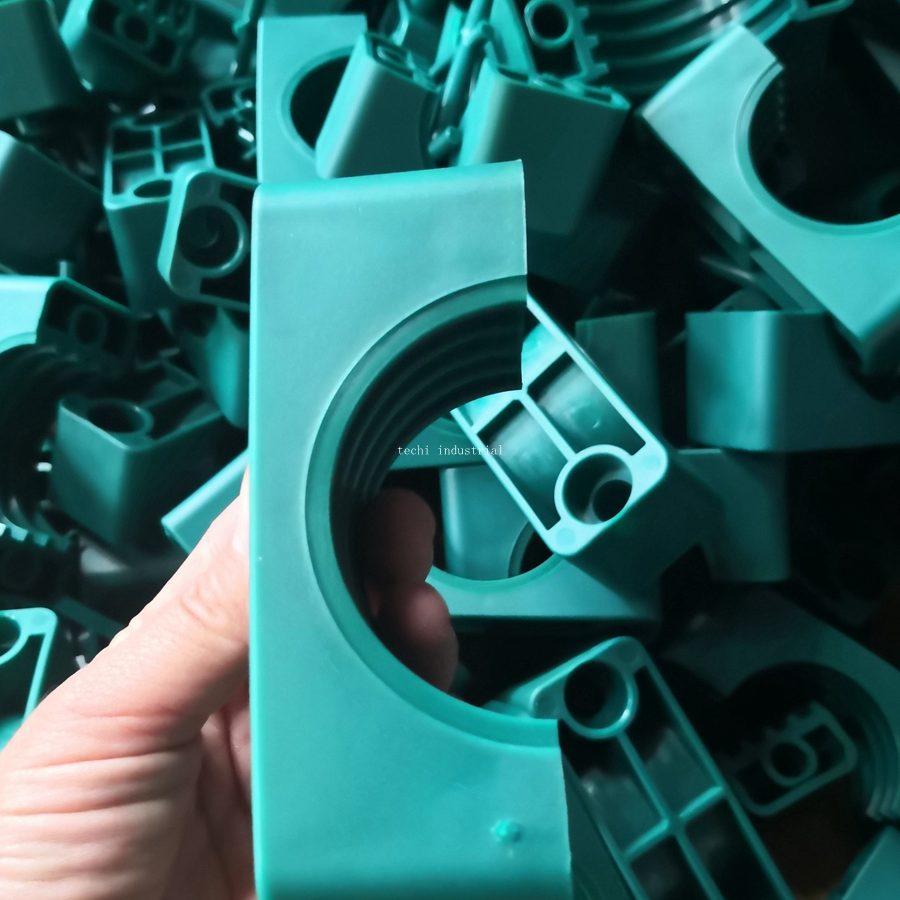

PP tube clamp body Sizes:6mm 6.3mm 9.5mm 8mm Working Temperature PP -30 degree up to +90 degree in dark green color PA -40 degree up to +120 degree in dark color AL -50°C up to +300°C Natural color Q235 -80°C up to +500°C Galvanizing or parkerising SUS304 or SUS316 -80°C up to +500°C Natural color

Polyamide PA Standard Series Tube Clamp Body 6mm 6.3mm 8mm 9.5mm 10mm

Techi Industrial is Polyamide Pipe Clamp manufacturer in CHINA. Polyamide Pipe Clamp are designed for locating wires, cables, and components in instruments, appliances, and electrical apparatus. These injection-molded clamps are used for both internal and external installations. The inside edges are smoothed to prevent cutting into cable insulation. Made of lightweight and durable plastic material, these P-shaped clamps are designed to secure cable, hose, and wire bundles by attaching them to existing holes. Techi industrial produce standard series pipe clamps DIN3015 Part 1,PP Polypropylene clamp body,polyamide PA clamp body,Aluminium AL clamp body,SA Thermoplastic Elastomer (87 Shore-A) clamp body.

standard series pipe clamps DIN3015 Part 1,PA polyamide tube clamp body 6mm 8mm,10mm

- Polypropylene standard series pipe clamps DIN3015 Part 1 size 6mm 6.3mm 8mm Material code: PP ,Colour: Green

- Polyamide PA standard series pipe clamps DIN3015 Part 1, 6mm 6.3mm 8mm

- Colour: Black Material code: PA Thermoplastic Elastomer (87 Shore-A) Colour: Black Material code: SA Material code: AL (Group 1A to 6)

- Aluminium AL Colour: Self-Colour

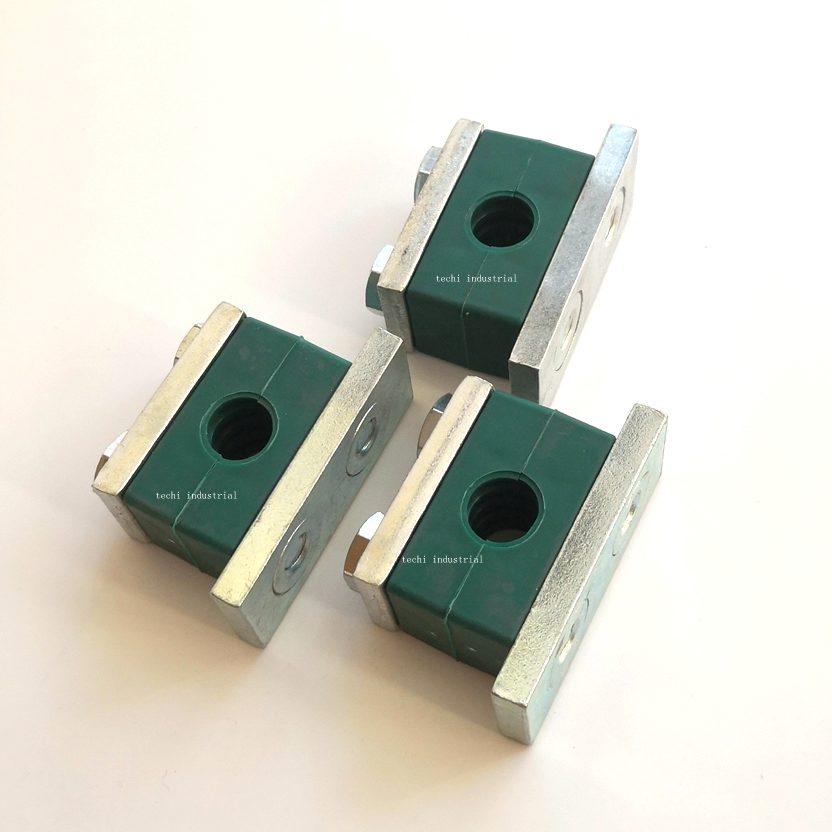

- standard series pipe clamps DIN3015 Part 1 size 6mm 6.3mm 8mm

- Series – Standard Series & Heavy Series

Standard Duty Tube Clamps DIN3015,Part 1

- Available to 2˝ tube outside diameter

- Recommended for systems with less than 1500 PSI operating pressure and no dynamic loads

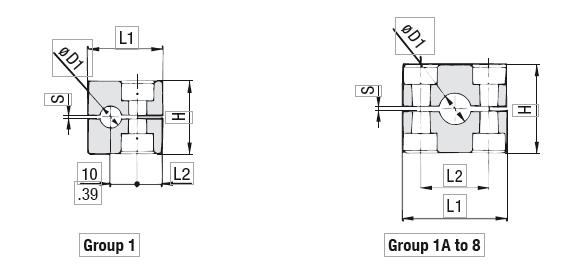

| Size | Bore Size | Recommended Nominal Size | Size | Bore Size | Recommended Nominal Size | ||||

| Inches | mm | Tube O.D | Pipe | Inches | mm | Tube O.D | Pipe | ||

| 0 | 0.24 0.25 0.31 0.37 0.39 0.47 | 6.0 6.4 8.0 9.5 10.0 12.0 | – 1/4˝ 5/16˝ 3/8˝ – – | – – – – 1/8˝ – | 4 | 1.05 1.10 1.18 | 26.6 28.0 30.0 | – – – | 3/4˝ – – |

| 1 | 0.24 0.25 0.31 0.37 0.39 0.47 | 6.0 6.4 8.0 9.5 10.0 12.0 | – 1/4˝ 5/16˝ 3/8˝ – – | – – – – 1/8˝ – | 5 | 1.26 1.33 1.38 1.50 1.57 1.65 | 32.0 33.7 35.0 38.0 40.0 42.0 | 1-1/4˝ – – 1-1/2˝ – – | – 1˝ – – – 1-1/4˝ |

| 2 | 0.50 0.54 0.55 0.59 0.63 0.67 0.71 | 12.7 13.7 14.0 15.0 16.0 17.1 18.0 | 1/2˝ – – – 5/8˝ – – | – 1/4˝ – – – 3/8˝ – | 6 | 1.75 1.90 2.00 | 44.5 48.3 50.8 | 1-3/4˝ – 2˝ | – 1-1/2˝ – |

| 3 | 0.75 0.79 0.84 0.87 0.91 0.98 1.00 | 19.0 20.0 21.3 22.0 23.0 25.0 25.4 | 3/4˝ – – – – – 1˝ | – – 1/2˝ – – – – | 7* | 2.37 2.5 2.87 3 | 60 .3 63.5 73 76.1 | – 2-1/2˝ – 3˝ | 2 – 2-1/2˝ – |

| 8* | 3.25 | 88.9 | – | 3˝ | |||||

Standard series / light duty stauff type polyamide pipe clamp Package and production lines