Heavy Duty Twin Series Pipe Clamp

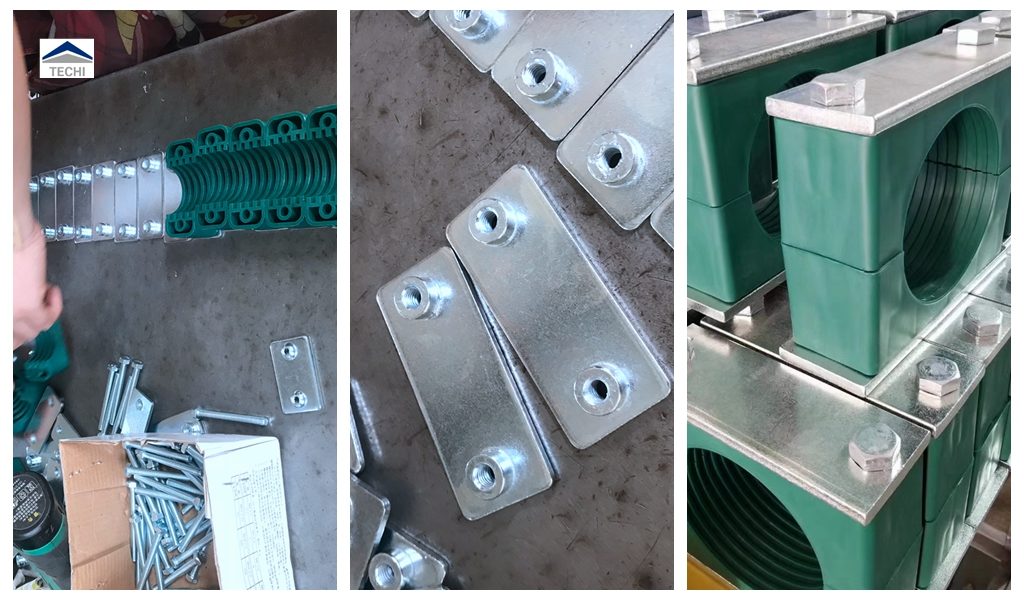

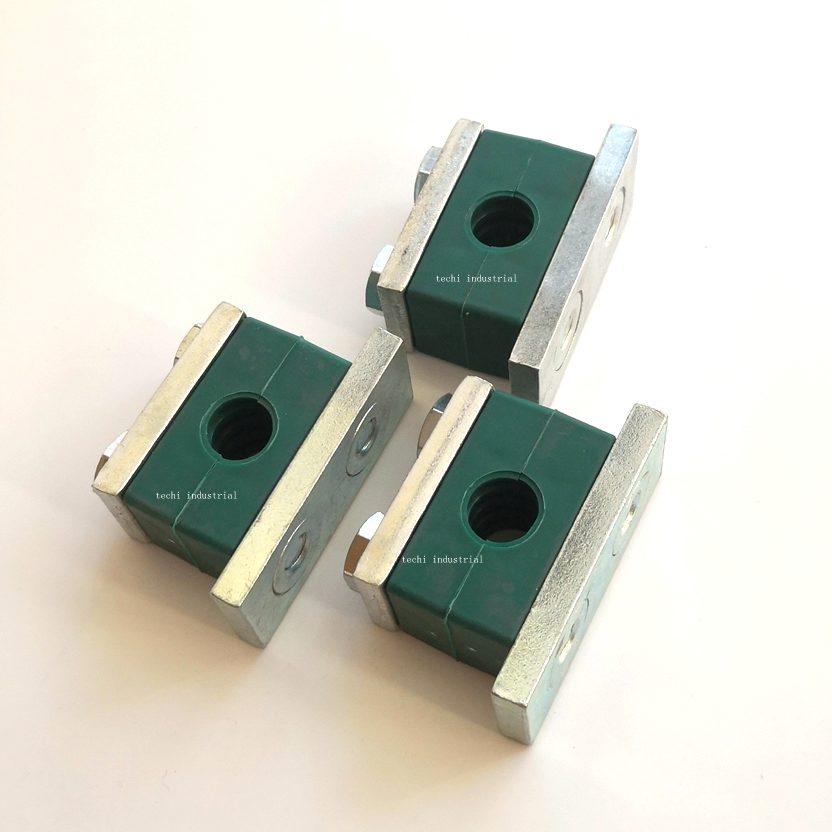

Structure:assembly including cover plate, weld plate, clamp body,hexagon bolts

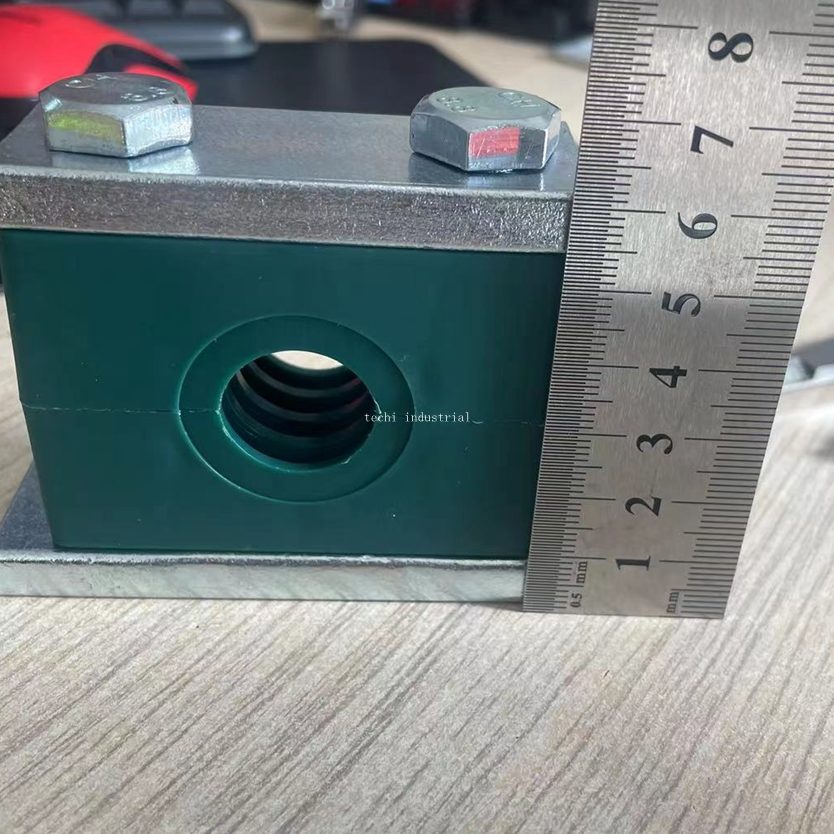

Sizes:Rang of O.D. 6mm to 42mm

Standard Series:according to DIN 3015

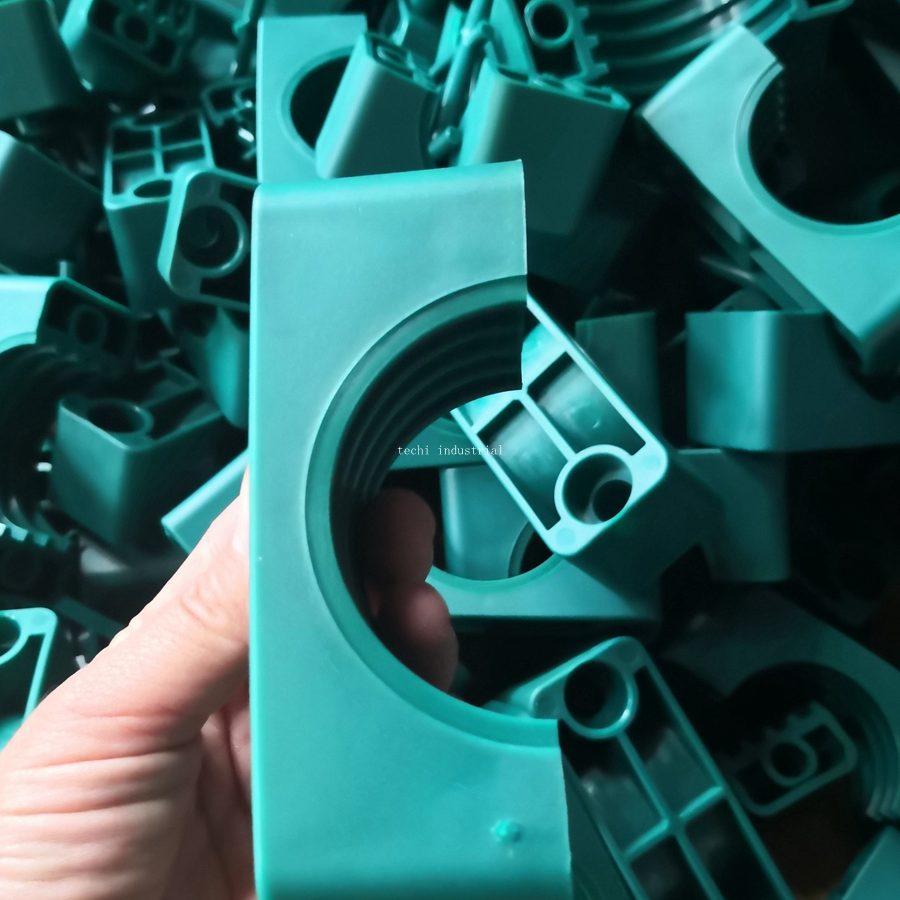

Working Temperature

PP(Polypropylene) -30 degree up to +90 degree in dark green color

PA (Polyamide)-40 degree up to +120 degree in dark color

AL(Aluminium) -50°C up to +300°C Natural color

Q235 -80°C up to +500°C Galvanizing or parkerising

SUS304 or SUS316 -80°C up to +500°C Natural color

Heavy Duty Twin Series Pipe Clamp

Techi industrial Co.,ltd is hydraulic pipe clamp factory and manufacturer in CHINA, Our products cover heavy series pipe clamp, light series pipe clamp, twin series pipe clamp, U form clamp, Saddle clamp,plastic pipe clamp,polyamide pipe clamp. Pipe clamp plates surface treatment:Electroplating (galvanizing, nickel plating, gilding, etc.), painting, heat treatment, carbonitriding, etching, powder painting, polishing, electroplating, sandblasting, anodizing, passivation

HEAVY SERIES HYDRAULIC PIPE CLAMPS are available in a single heavy (SH) unit two (2) bolt design, or a double heavy (DH) unit four (4) bolt design.

Twin pipe clamp series can be supplied in 5 series for normal mechanical stress,tube O.D 6 to 42mm.( 6~42mm)

Twin Series Pipe Clamp size 6mm 8mm 10mm 12mm 12.7mm 14mm 15mm 16mm 17mm18mm 19mm 20mm 21.3mm 22mm 23mm 25mm 26.9mm 28mm 30mm 30mm 32mm 33.7mm

35mm 38mm 40mm 42mm ,double holes pipe clamp

| Properities | Polypropylene(PP) | Polyamide(PA) | Aluminium(AL) |

| Density | 0.906/cm³ | 1.12-1.15g/cm³ | 2.9-3.2g/cm³ |

| Flexural Deflection | 36N/mm² | 130-200N/mm² | 170N-400N/mm² |

| Impact Resistance | No Break | No Break | No Break |

| Compressive strength | 90N/mm² | 120N/mm² | 60-80HB5/250 |

| Modulus of Elasticity |

1500N/mm² | 3000N/mm² | 70000N/mm² |

| Tensile Strength | 25-35N/mm² | 80-90N/mm² | 180-300N/mm² |

| Temp.Resistance | -30~+90℃ | -40~120℃ | -75~300℃ |

| Colour | Dark Green or customized colour |

Black,Green or customized colour |

Silver white |

Heavy Duty Hydraulic Pipe Clamp Double Hole size:

| Size | Bore Size | Recommended Nominal Size |

Size | Bore Size | Recommended Nominal Size |

||||

| Inches | mm | Tube O.D |

Pipe | Inches | mm | Tube O.D |

Pipe | ||

| 1 | 0.24 0.25 0.32 0.37 0.39 0.41 0.47 |

6.0 6.4 8.0 9.5 10.0 10.3 12.0 |

– 1/4˝ 5/16˝ 3/8˝ – – – |

– – – – 1/8˝ 1/8˝ – |

4 | 1.05 1.10 1.18 |

26.7 28.0 30.0 |

– – – |

3/4˝ – – |

| 2 | 0.50 0.54 0.55 0.59 0.63 0.67 |

12.7 13.7 14.0 15.0 16.0 17.1 |

1/2˝ – – – 5/8˝ – |

– 1/4˝ – – – 3/8˝ |

5 | 1.26 1.33 1.38 1.50 1.60 1.65 |

32.0 33.7 35.0 38.0 40.0 42.0 |

1-1/4˝ – – 1-1/2˝ – – |

– 1˝ – – – 1-1/4˝ |

| 3 | 0.75 0.79 0.84 0.87 0.91 0.98 1.00 |

19.0 20.0 21.3 22.0 23.0 25.0 25.4 |

3/4˝ – – 7/8˝ – – 1˝ |

– – 1/2˝ – – – – |

|||||

Heavy series Twin Pipe Clamp manufacturer: