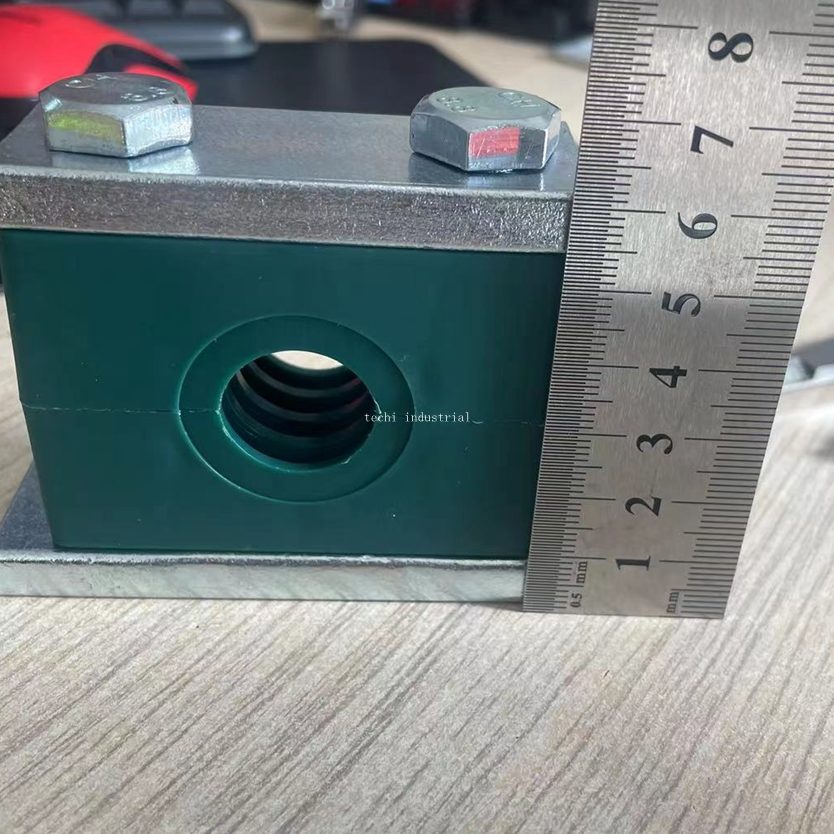

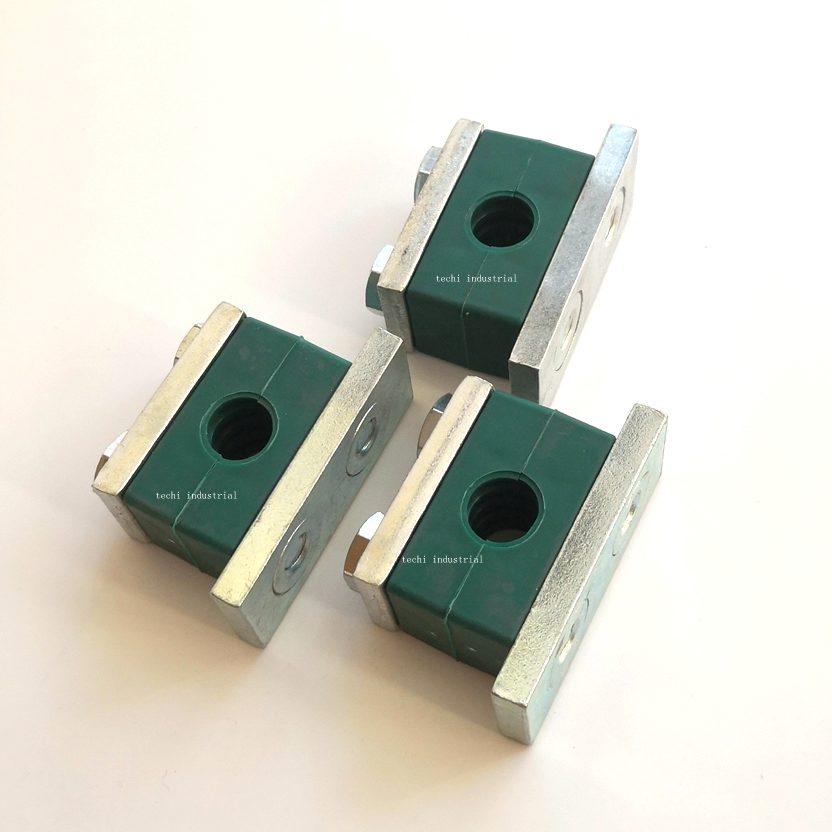

Hydraulic Heavy Duty Pipe Clamp Halves and Body Green Colour

Structure:assembly including cover plate, weld plate, clamp body,hexagon bolts

Sizes:6mm 10mm 12mm 20mm 32mm till 406mm used for factory water pipes.hydraulic hose pipes.

Working Temperature

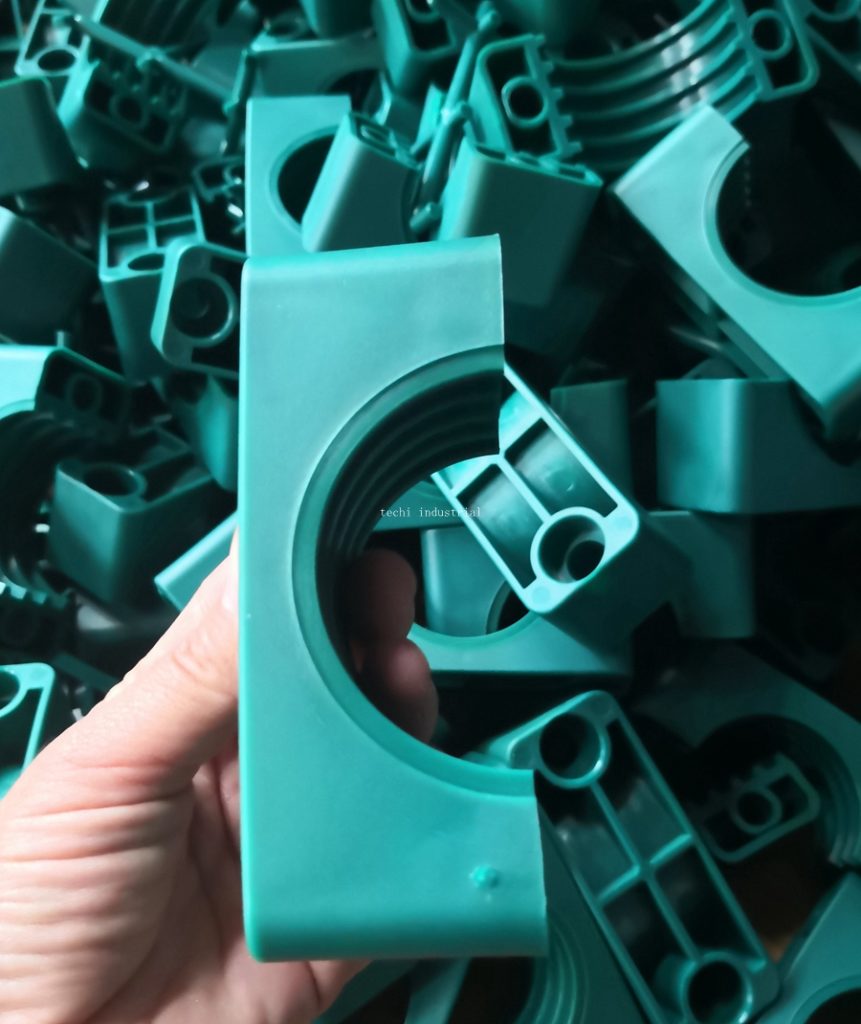

PP -30 degree up to +90 degree in dark green color

PA -40 degree up to +120 degree in dark color

AL -50°C up to +300°C Natural color

Q235 -80°C up to +500°C Galvanizing or parkerising

SUS304 or SUS316 -80°C up to +500°C Natural color

Heavy Series Pipe & Tube Clamp Halves Plastic Green

Techi industrial and Trade Co.,ltd is hydraulic pipe&tube clamp factory and manufacturer in CHINA, Our products cover hydraulic heavy series pipe&tube clamp body plastic green colour,hydraulic light/standard series pipe&tube clamp insert, twin series pipe tube clamp,Rail nut pipe clamp body PP green colour,mounting rail TS11 TS14 in material of iron steel,stainless steel 304 316, U form clamp, Saddle clamp,plastic PVC pipe clamp,polyamide pipe clamp,plastic polypropylene pipe clamp,Single plastic heavy pipe clamp.

Pipe clamp plates surface treatment:Electroplating (galvanizing, nickel plating, gilding, etc.), painting, heat treatment, carbonitriding, etching, powder painting, polishing, electroplating, sandblasting, anodizing, passivation

Hydraulic pipe clamp size and type:

Hydraulic pipe clamps are designed and made according to German standard DIN 3015. These products can be divided into three main types as below:

1) Standard series stauff type pipe clamps designed according to German standard DIN 3015 part 1: This kind of pipe clamps are the most popular, they are the light duty pipe clamps.

2) Heavy duty pipe clamps according to standard DIN 3015 part 2: This kind of pipe clamps are designed for high pressure, high vibration applications.

3) Twin series pipe clamps designed and made according to German standard DIN 3015 part 3: This kind of pipe clamps are used to clamp two tubes or pipes in parallel.

Light duty tube clamps (according to DIN 3015 Part 1) are available in 7 standard group sizes for normal mechanical requirements. The clamp body is available in a grooved and smooth version.

Other accessories including welding base plates, rail supports, rail nuts, cover plates, bolts and construction types.

Heavy duty pipe clamps (according to DIN 3015 Part 2) are designed for high mechanical pressure and high viration applications, and are available in 8 group sizes.

The clamp body is available in a grooved and smooth design. Other components are including welding base plates, rail supports, rail nuts, cover plates, bolts and construction types.

The design is according to DIN 3015 – both upper and lower clamp-halves are identical. The grooved webs inside the bores of the clamps provide an impact and vibration-deadening effect and absorb the forces towards the direction of the tube axis.

And when clamping hoses and cables, Techi recommends the use of clamp halves with a smooth bore.

Twin series pipe clamps (according to DIN 3015 Part 3) are available as a twin tube clamp in 5 group sizes. The clamp body is available in a groove/smooth design. Other components are including welding base plates, rail supports, rail nuts, cover plates, bolts and construction types. Clamp halves could be with same diamters or with different diameters. Clamp body with different diameter is only possible when used together.

Usually metal parts are in carbon steel with zinc-coated, zinc-nickle coated or phosphated surface treament. All metal parts are also available in stainless steel. Other materials upon request.

Stainless steel qualitities are to 1.4401/1.4301 (AISI 316/304), resistant to rust and acid.

Pipe clamp series range:

Light series clamp can be supplied in 8 series for normal mechanical stress,tube O.D 6 to 102mm.

(6~102mm)

Heavy series clamps can be supplied in 11 series for high mechanical stress,Tube O.D 6 to 508mm.( 6~508mm)

Twin pipe clamp series can be supplied in 5 series for normal mechanical stress,tube O.D 6 to 42mm.( 6~42mm)

| Properities | Polypropylene(PP) | Polyamide(PA) | Aluminium(AL) |

| Density | 0.906/cm³ | 1.12-1.15g/cm³ | 2.9-3.2g/cm³ |

| Flexural Deflection | 36N/mm² | 130-200N/mm² | 170N-400N/mm² |

| Impact Resistance | No Break | No Break | No Break |

| Compressive strength | 90N/mm² | 120N/mm² | 60-80HB5/250 |

| Modulus of Elasticity |

1500N/mm² | 3000N/mm² | 70000N/mm² |

| Tensile Strength | 25-35N/mm² | 80-90N/mm² | 180-300N/mm² |

| Temp.Resistance | -30~+90℃ | -40~120℃ | -75~300℃ |

| Colour | Dark Green or customized colour |

Black,Green or customized colour |

Silver white |

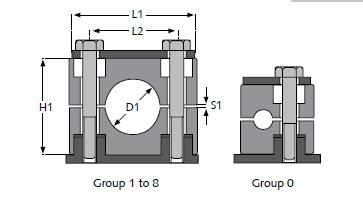

Hydraulic Heavy series pipe&tube clamp size:

6mm,6.4mm,8mm,9.5mm,10mm,12mm,12.7mm,13.5mm,14mm,15mm,16mm,17.2mm 18mm,20mm,21.3mm 22mm,25mm 25.4mm 26.9mm 28mm 28.6mm 30mm 32mm 33.7mm 35mm 38mm 40mm 41.3mm 42mm 44.5mm 48.4mm 50.8mm 54mm 57.2mm 60.3mm 63.5mm 70mm 73mm 76.1mm 88.9mm 102mm,108mm 114mm 127mm 133mm 140mm 152mm 159mm 165mm 168mm 177.8mm 193.7mm 203mm 216mm 219mm 273mm 324mm 356mm 406mm, hydraulic heavy duty pipe clamp group 1,group 2,group 3S,group 4S,group 5S,group 6S,group 7S group 8S group 9S,group 10S group 11S group 12S

Heavy Series Pipe Clamp Half and Body:

| Tube OD (D1) | Group size |

H1 |

L1 |

L2 |

S1 |

Insert

width |

Thread |

TubeOD (D1) | Group size |

H1 |

L1 |

L2 |

S1 |

Insert width |

Thread |

| 6 |

1 |

32 |

55 |

33 |

0.6 |

30 |

M10 |

65 |

5 |

120 |

152 |

122 |

2 |

60 |

M16 |

| 6.4 | 70 | ||||||||||||||

| 8 | 73 | ||||||||||||||

| 9.5 | 75 | ||||||||||||||

| 10 | 76.1 | ||||||||||||||

| 12 | 80 | ||||||||||||||

| 12.7 | 82.5 | ||||||||||||||

| 13.5 | 88.9 | ||||||||||||||

| 14 | 88.9 |

6 |

170 |

206 |

168 |

80 |

M20 |

||||||||

| 15 | 100 | ||||||||||||||

| 16 | 102 | ||||||||||||||

| 17.2 | 108 | ||||||||||||||

| 18 | 114 | ||||||||||||||

| 19 |

2 |

48 |

70 |

45 |

127 | ||||||||||

| 20 | 133 | ||||||||||||||

| 21.3 | 133 |

7 |

200 |

251 |

205 |

3 |

90 |

M24 |

|||||||

| 22 | 140 | ||||||||||||||

| 25 | 152 | ||||||||||||||

| 26.9 | 159 | ||||||||||||||

| 28 | 165 | ||||||||||||||

| 30 | 168 | ||||||||||||||

| 30 |

3 |

60 |

85 |

60 |

168 |

8 |

270 |

336 |

265 |

120 |

M30 |

||||

| 32 | 177.8 | ||||||||||||||

| 33.7 | 193.7 | ||||||||||||||

| 35 | 216 | ||||||||||||||

| 38 | 219 | ||||||||||||||

| 40 | 219 |

9 |

410 |

470 |

395 |

8 |

162 |

||||||||

| 42 | 273 | ||||||||||||||

| 38 |

4 |

90 |

115 |

90 |

2 |

45 |

M12 |

324 | |||||||

| 42 | 356 | 10 | 530 | 630 | 534 | 20 | 182 | ||||||||

| 44.5 | 406 | ||||||||||||||

| 48.3 | |||||||||||||||

| 50.8 | |||||||||||||||

| 55 | |||||||||||||||

| 57 | |||||||||||||||

| 60.3 | |||||||||||||||

| 63.5 | |||||||||||||||

| 65 | |||||||||||||||

| 70 | |||||||||||||||