Non-Metal Pipe Repair Clamp GF

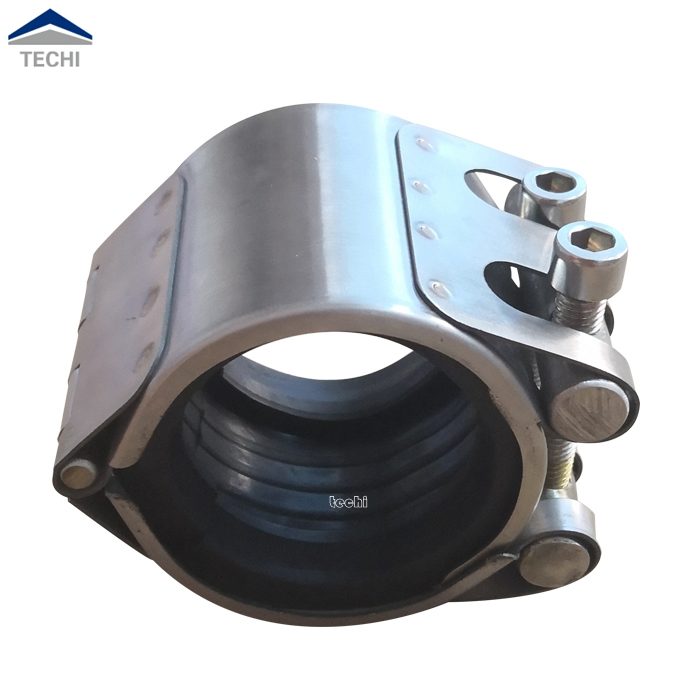

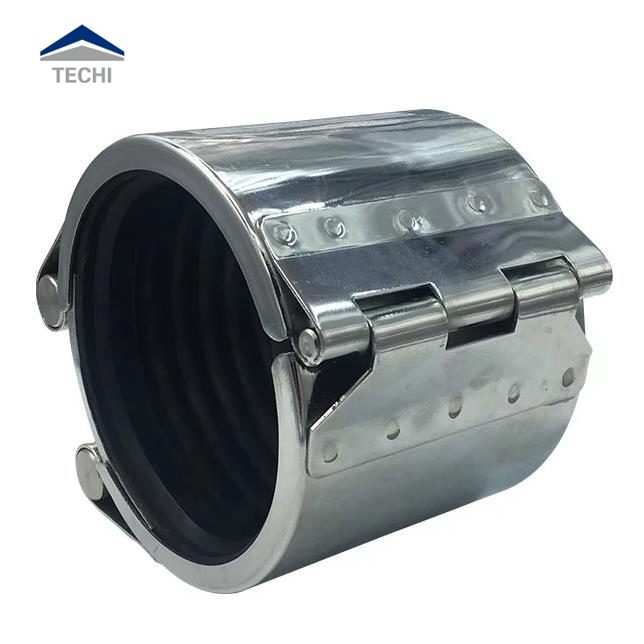

Main Parts:Shell,Bridge Plate,Bolts,Nuts and Washers,Lift-bars and Receiver-lugs

Surface treatment:Acid pickling and passivation

Passivated:Chemically treated after welding for corrosion-resistant coating

Rubber sealing gasket:EPDM/NBR/SILICONE/VITON/GORE-TEX

Bolts:SUS304/316,or cast iron with Q235B galvanization

Nuts:SUS304/316,or cast iron with Q235B galvanization

Washer:SUS304/316,or cast iron with Q235B galvanization

Non-Metal Pipe Repair Clamp GF

Pipe Connection applied to connection of various kinds of metal pipes and composite materials of pipelines.

Pipe Repair Clamp GF series creates a unique pipeline connection technology with its original design. It breaks through the traditional connection concept, and uses stainless steel and rubber to make components combination device to achieve the sealing and pressure bearing function.

The pipe repair clamp pipeline connection allowable angular deflection, provide restraint and strong sealing. It can provide safe, fast and steady connection and very good effect of anti-vibration and noise reduction.

As well as the function of distance compensation in pipe ends. Easy to be installed and disassembled and reusable.

| Product Name | GF copper ring pipe repair clamp |

| Material | Stainless steel and copper |

| Color | Silver |

| Size | from 62-64mm to 796-804mm |

| Usage | Pipe quick easy pipe repair clamp |

| In-House Test | Hydrostatic Test/Impulse Test/Vibration Test/Salt Spray Test |

| Application | Water ,gas,oil pipeline |

| Certification | ISO9001, WRAS, CE , GHOST |

| Shipment Flexibility | Mix load according to customer requirement |

| Payment Terms: | T/T , Western Union , MoneyGram , PayPal , Ect. |

Specification of pipe repairing clamp GF

| Pipe O.D. | O.D.Range | Industry | Dimensions | Screws | Screw Torque |

|||

| OD | ODmin— ODmax |

WP | Cmax | L | D | H | ||

| clamped | ||||||||

| (mm) | (mm) | (bar) | (mm) | (mm) | approx(mm) | approx(mm) | M | Nm |

| 63 | 62-64 | 20 | 10 | 75 | 85 | 105 | 8 | 25 |

| 75 | 74-76 | 20 | 25 | 105 | 100 | 120 | 8 | 30 |

| 90 | 89–91 | 20 | 25 | 105 | 110 | 130 | 8 | 40 |

| 110 | 108-111 | 20 | 25 | 120 | 130 | 150 | 10 | 40 |

| 125 | 123-126 | 20 | 25 | 120 | 145 | 165 | 10 | 50 |

| 140 | 138-142 | 20 | 30 | 120 | 160 | 180 | 10 | 50 |

| 160 | 158-162 | 20 | 30 | 120 | 180 | 200 | 10 | 60 |

| 180 | 178-182 | 16 | 35 | 152 | 210 | 240 | 12 | 60 |

| 200 | 198-203 | 16 | 35 | 152 | 230 | 260 | 12 | 60 |

| 225 | 222-227 | 16 | 35 | 152 | 255 | 285 | 12 | 60 |

| 250 | 247-253 | 16 | 35 | 152 | 280 | 310 | 12 | 60 |

| 280 | 277-283 | 16 | 35 | 152 | 310 | 345 | 12 | 60 |

| 315 | 311-317 | 16 | 35 | 152 | 345 | 375 | 12 | 60 |

| 355 | 351-357 | 16 | 35 | 152 | 385 | 415 | 12 | 60 |

| 400 | 396-402 | 12 | 35 | 152 | 430 | 460 | 12 | 60 |

| 450 | 447-453 | 12 | 35 | 152 | 480 | 510 | 12 | 60 |

| 500 | 497-503 | 12 | 35 | 152 | 530 | 560 | 12 | 70 |

| 560 | 557-563 | 10 | 35 | 152 | 590 | 620 | 12 | 70 |

| 630 | 627-633 | 10 | 35 | 152 | 660 | 690 | 16 | 70 |

| 800 | 796-804 | 10 | 35 | 152 | 830 | 860 | 16 | 80 |

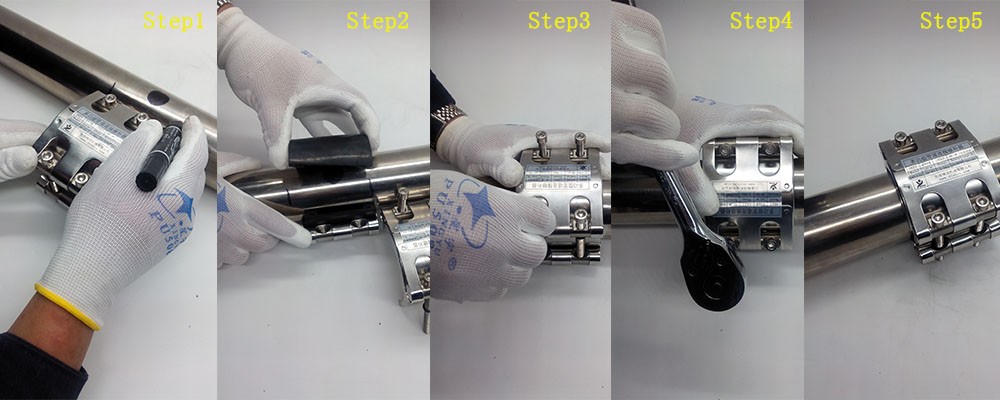

Installation for pipe repair clamp: