How to install Standard Series Pipe Clamps (DIN 3015-1)

Standard Series Pipe Clamps, also known as Light Series hydraulic pipe clamp, Light duty tube clamp,are based on DIN 3015-1 specifications to provide robust support, excessive vibration dampening, and noise reduction for industrial piping in modern hydraulic and pneumatic systems.

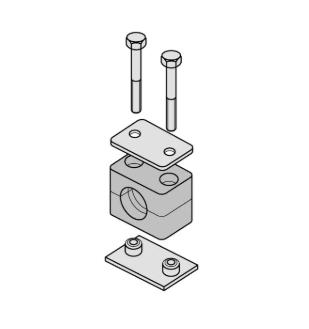

A high-performance pipe clamp assembly is more than just a bracket. It is a modular system designed for durability and precision. Based on the industry-leading design, a complete light series pipe tube clamp set includes:

Weld Plate (SP): The structural base designed for permanent mounting via welding bottom plates.

Lower Clamp Body: The bottom half of pipe clamp body.

Upper Clamp Body: The symmetrical top half clamp body that completes the circular grip clamp body.

Cover Plate (DP): A clamps plates is metal reinforcement that distributes bolt tension and prevents clamps polymer fatigue.

Hexagon Head Bolts (AS): High-tensile fasteners that lock the entire assembly to the base.

2. Pipe Clamp Material Specification

Selecting the correct material of pipe clamp body is vital for ensuring Corrosion Resistance and operational longevity in harsh environments.

Clamp Body Materials:

Polypropylene (PP): Color-coded Green Yellow Black Blue etc. Ideal for standard hydraulic applications with temperatures ranging from -30°C to +90°C. It offers excellent corrosion resistance.

Polyamide (PA): Color-coded Black. Best for high-stress environments (-40°C to +120°C) due to its superior impact strength and flame-retardant properties.

Aluminum (AL): Recommended for extreme heat applications (up to +300°C) or where maximum mechanical grip is required.

Thermoplastic Elastomer (SA): For specialized noise-sensitive environments, providing maximum Vibration Isolation.

Light duty pipe clamp plates surface treatment finishes:

W2 (Zinc/Nickel Plated): High-grade carbon steel with superior anti-rust coating.

W4 (AISI 304 Stainless Steel): Polishing of surface.

W5 (AISI 316 Stainless Steel): The standard for Marine and Offshore applications, offering peak resistance to salt spray and chemicals.

3. Comprehensive Light Pipe Clamp Sizing&Groups

Light duty pipe clamps are categorized into Groups (1 to 8) to accommodate a wide range of pipe O.D. (Outer Diameter).

| TECHI Group | DIN Group | Pipe OD (mm) | Weld Plate Length (L1) | Bolt Thread (G) |

| Group 1 | 0 | 6 – 12 mm | 31.5 mm | M6 |

| Group 1A | 1 | 6 – 12 mm | 36 mm | M6 |

| Group 2 | 2 | 12.7 – 18 mm | 42 mm | M6 |

| Group 3 | 3 | 19 – 25.4 mm | 50 mm | M6 |

| Group 4 | 4 | 26.9 – 30 mm | 60 mm | M6 |

| Group 5 | 5 | 32 – 42 mm | 71 mm | M6 |

| Group 6 | 6 | 44.5 – 54 mm | 88 mm | M6 |

Installation Procedure: Step-by-Step

Proper installation ensures the longevity of the hydraulic system. Follow these steps for light series pipe clamp assembly:

Position the Weld Plate: Place the single weld plate (bottom plate) on the supporting structure and weld it into place. Ensure the threaded nuts are facing upwards.

Seat the Clamp Body: Take the two halves of the plastic clamp body and place the bottom half onto the weld plate. The alignment pins/holes of the clamp body should match the position of the nuts.

Insert the Pipe: Place the pipe, tube, or hose into the profiled groove of the bottom clamp half.

Add the Top Half & Cover Plate: Place the second half of the clamp body over the pipe. Then, place the galvanized metal cover plate on top. Ensure the two holes in the cover plate align perfectly with the holes in the clamp body and the threads in the weld plate.

Secure with Bolts: Insert two hex bolts (typically M6 for light series) through the cover plate and clamp body. Tighten them into the weld plate nuts. Do not over-tighten; the “tension clearance” (S) between the clamp halves ensures the pipe is gripped firmly without being crushed.

Key Advantages of Light Series Pipe Clamps

Vibration Dampening: The profiled inside surface with tension clearance provides excellent grip and vibration absorption.

Corrosion Resistance: Zinc-plated or stainless steel components withstand harsh environments.

Standardization: Built according to DIN 3015, ensuring compatibility with international hydraulic systems.

By following these manufacturing and installation standards, you can ensure a reliable and vibration-free piping system.