Insulated U Bolt Clamp 2 1/2″ Grip Type

U-Bolt is T316 Stainless steel

Sleeve and Pad are made from ribbed rubber inner face

BOLT WITH PTFE COATED

Insulated U Bolt Clamp 2 1/2″ Grip Type

Techi Industrial are manufactured from a high quality zinc plated,stainless steel 304 316 metal u-bolt with a fire retardant moulded sleeve that does not support the surface travel of flame.

Rubber Lined U Bolt Grip Type Material:

Anti-Vibration Rubber Lined U-bolt and Backing pad 65 mm ID

U-Bolt is T316 Stainless steel

Sleeve and Pad are made from , a high performance silicone compound designed for high temperature applications. It has a good resistance to seawater and excellent resistance to steam.

Bolt with PTFE coating,These include resistance to corrosion and chemical attack, superb subsea visibility, lower maintenance costs and less downtime.

Temperature range: -40°F to 250°F (-40°C to 120°C)

Hardness (IRHD): 65-75

Tensile Strength (Mpa) : 1.4 (min)

Lateral Flow (% @ load 0.35 Mpa): 0.28

Lateral Flow (% @ load 0.70 Mpa): 0.45

Recovery (% @ compression load 2.75 Mpa) : 90

Load bearing capacity (static load Mpa) : 0.70

C/W 2 nuts on each leg

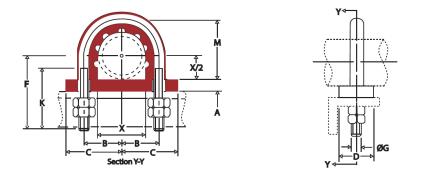

Rubber Lined U Bolt Grip Type dimention:

NB = 65 mm

Pipe O/D = 81 mm

B = 99 mm

C = 120 mm

F = 100 mm

G (Bar Diameter) = M12

K = 75 mm

M = 74 mm

X = 73 mm

D*A (backing pad) = 60*10 mm

Advantages:

– Reduce or eliminate noise and fatigue due to vibration of pipework against the supporting structure

– Prevention of galvanic corrosion due to the contact of dissimilar metals in the presence of an electrolyte

– Prevention of wear and / or crushing of composite, thin wall or non-ferrous pipework

Also available in Zinc plated or galvanised steel. Please contact us for details

Insulated U bolts clamp engineered to secure pipes, cables, and machinery while providing electrical insulation, vibration dampening, and long-term corrosion protection. Ideal for offshore industries, solar farms, marine equipment, FPSO / FSO projects, and industrial installations, our insulated U bolts meet global standards for safety and performance.

| Name | Details |

| Sizes | Fit for pipe size OD 1/2″ to 36″(DN15-DN900), U bolt dia 1/4″ to 20″ (M6 to M56) |

| Material | Carbon steel (HDG coated) / Stainless steel 304/316 / Alloy steel |

| Insulation Sleeve | EPDM, Neoprene, or Silicone Rubber (flame-retardant options available); PTFE(Teflon) coated, Plastics as PVC and so on. |

| Temperature Range | -40°F to 250°F (-40°C to 120°C) |

| Standards | ASTM A 193 B7 /ASTM A194 2H, ASTM A320 B8M/ASTM A194 8M, ASTM A320 B8/ A194 8, ASTM A320 L7/ASTM A194 7, ASTM A325, ASTM A307, A153, ASME B18.2.6, ISO 4032, and so on. |

| Surface Coating | Hot dipped Galvanized(HDG) for non-stainless steels, PTFE coated (as Xylan 1014, Xylan 1024, Xylan 1070 and so on) for stainless steels U bolts. |

| Certifications | ISO 9001, RoHS compliant, salt spray tested (2,000+ hours) |

· Grip type insulated U bolts

Our Grip-Type Insulated U-Bolt Pipe Clamps minimize vibration transfer and prevent galvanic corrosion between pipes and hangers. Designed with EPDM/Neoprene sleeves, they isolate dissimilar metals, ideal for marine, chemical, and HVAC systems. The grip configuration securely holds pipes while allowing small axial and torsional movements, accommodating thermal expansion or mechanical stress. Made from hot-dip galvanized steel or stainless steel 304/316, these clamps ensure durability in harsh environments, offering a reliable, maintenance-free solution for long-term performance.

· Non-grip type insulated U bolts

Non-grip type U bolts are known as guide type U bolts too. it is a specialized insulated U bolt designed to secure pipes or cables while allowing controlled linear movement along a fixed axis. Unlike grip-type U bolts, it does not tightly clamp the pipe but instead uses a loose fit or PTFE-lined channel to guide the pipe during thermal expansion or contraction. This design prevents stress on the piping system while maintaining alignment.

Commonly used in HVAC, industrial piping, and marine applications, guide-type U bolts are made from hot-dip galvanized steel or stainless steel for corrosion resistance. They are ideal for systems requiring flexibility, such as steam lines or chilled water pipes, ensuring long-term reliability without compromising structural integrity.

By insulate materials:

1. Rubber insulated U Bolts Clamp

1. EPDM Rubber Insulated U Bolt Clamp

- Weather-resistant and UV-stable, ideal for outdoor applications like solar farms and marine structures.

2. Neoprene Insulated U Bolts Clamp

- Oil and chemical-resistant, commonly used in industrial and automotive environments.

3. Silicone Rubber Insulated U Bolts Clamp

- Heat-resistant up to 260°C, suitable for high-temperature applications such as HVAC systems.

This type of U bolts also are known as Rubber coated U bolts or U bolts with rubber sleeve.

1. PTFE (Teflon) Insulated U Bolts Clamp

- High-temperature and chemical-resistant, perfect for harsh environments like chemical plants.

2. Plastic-Coated Insulated U Bolts

- Lightweight and cost-effective, used for electrical insulation in low-stress environments.

3. Flame-Retardant Insulated U Bolts

- Designed with fire-resistant materials (e.g., flame-retardant EPDM), essential for safety-critical installations.

By U bolt materials and its coating:

1. Hot-Dip Galvanized Insulated U Bolts Clamp

- Zinc-coated for enhanced corrosion resistance, ideal for marine and offshore applications.

2. Stainless Steel Insulated U Bolts Clamp

- Made from 304/316 stainless steel for maximum durability in corrosive environments like saltwater.

3. FluoroPolymer Coated U bolts Clamp

- Xylan coated U bolts, PTFE coated U bolts Clamp,

Grip Type Rubber Lined U bolt Clamp Package:

Insulated U-Bolt Pipe Supports/ Clamps (Guide Type) have been specifically designed to minimise vibration transmission between pipework and hanger, and also preventing corrosion between dissimilar metals. The configuration of PTFE lined elastomer components enables the accommodation of larger axial and torsional pipe movements, allowing the pipe to slide.

| Payment & Shipping Terms | Supply Capacity | ||

| Payment Term: | L/C, Western Union, D/P, T/T | Production Capacity: | 80000 Per Day |

| MOQ: | 500 Piece/Pieces | Packing: | 100/carton |

| Means of Transport: | Land, Ocean,Air | Delivery Date: | 15 working day |